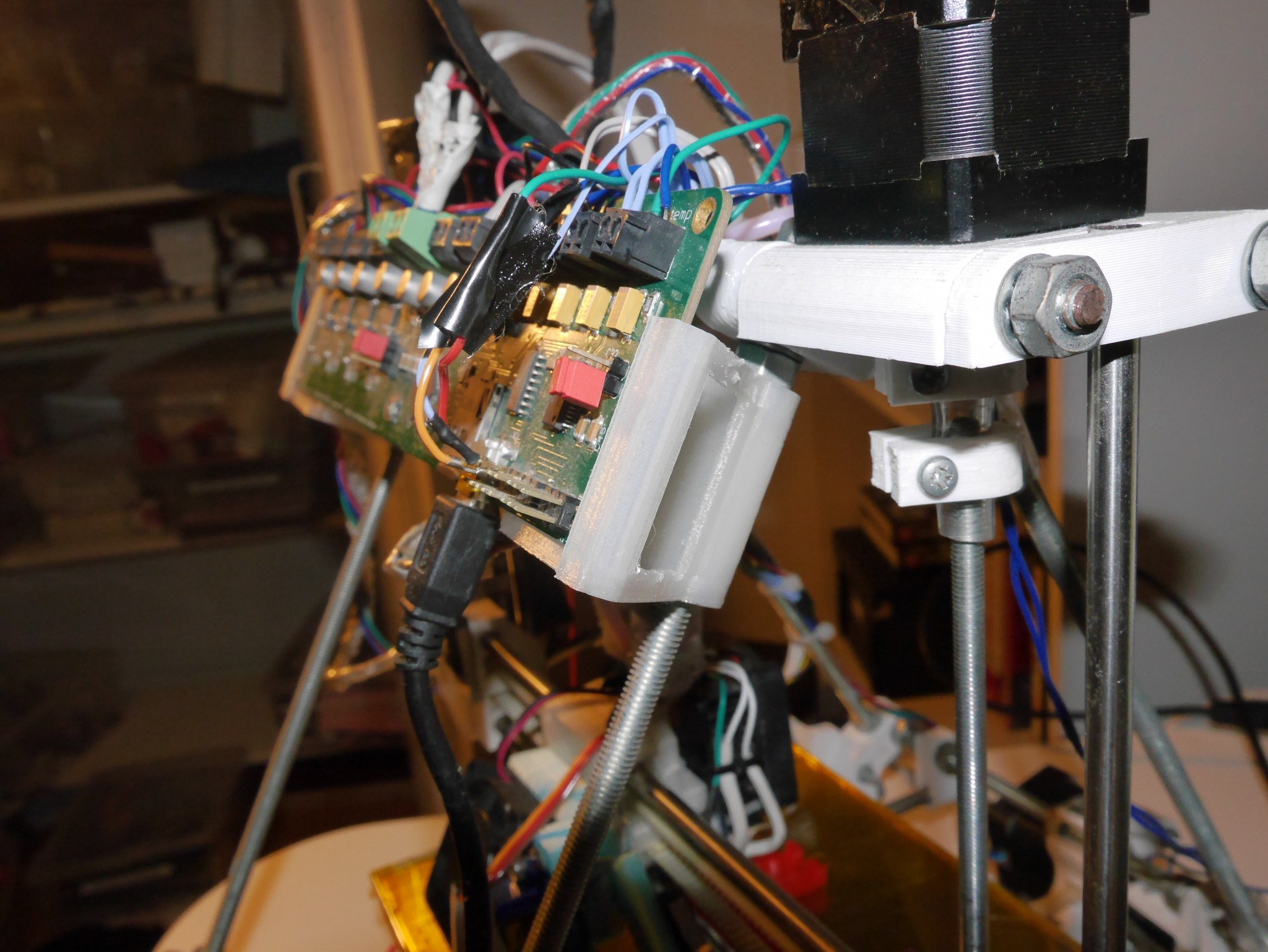

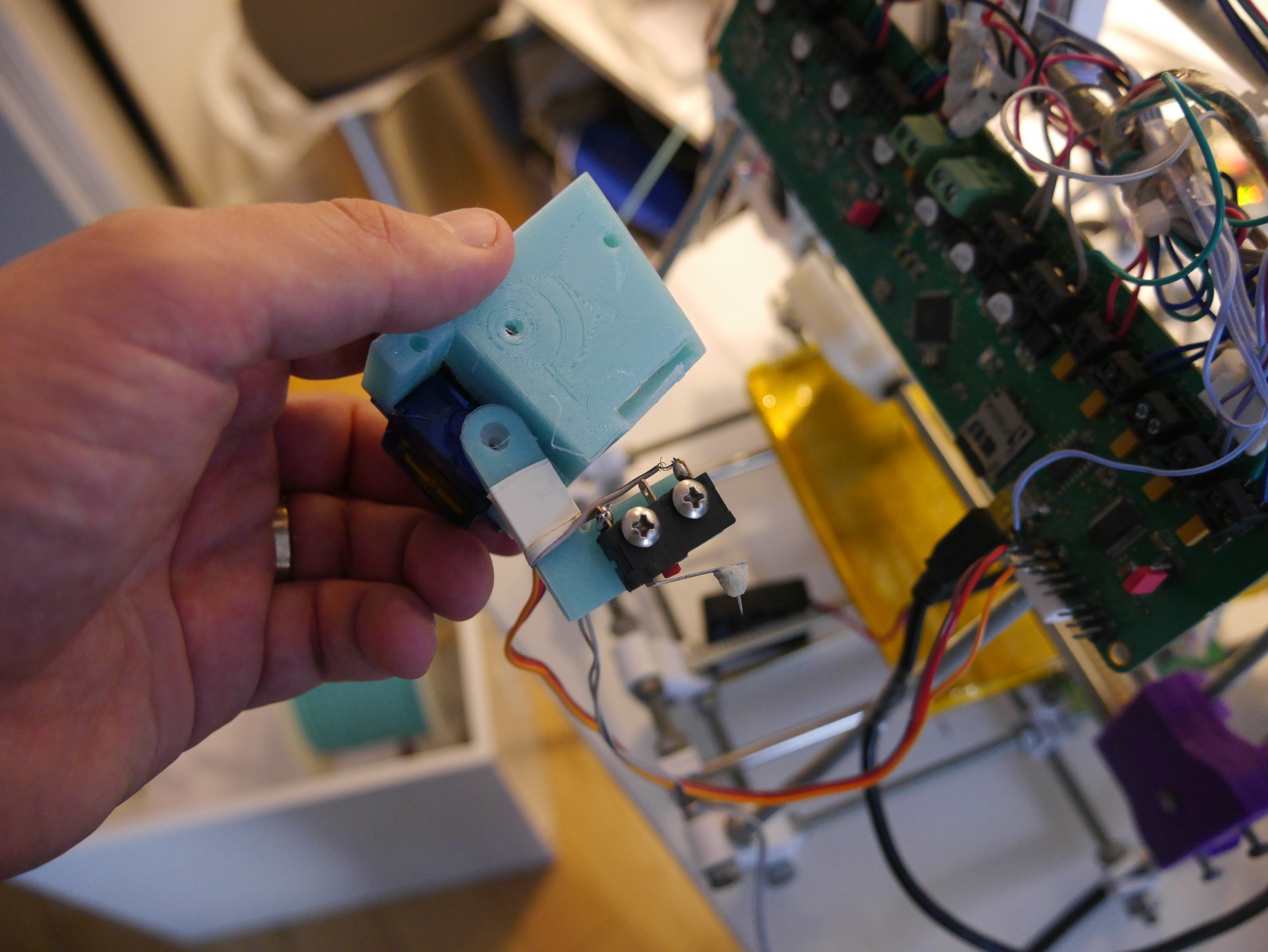

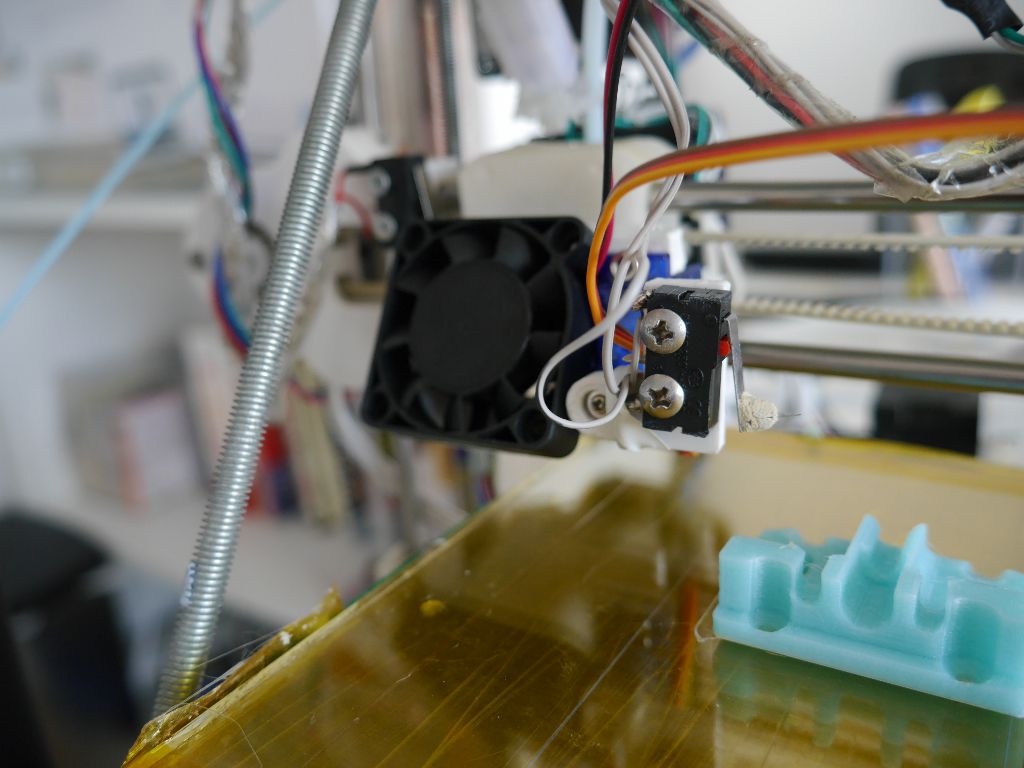

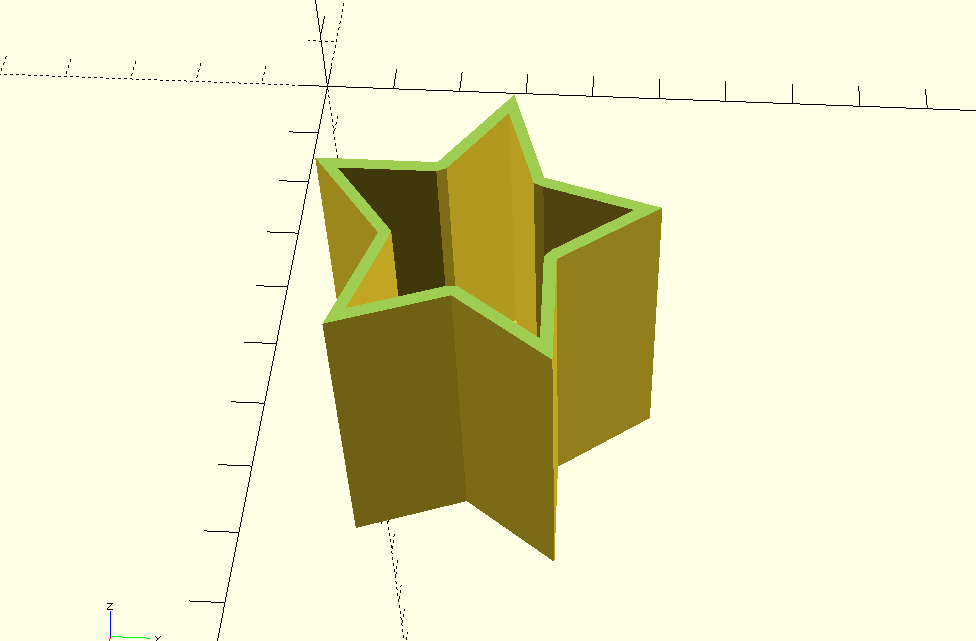

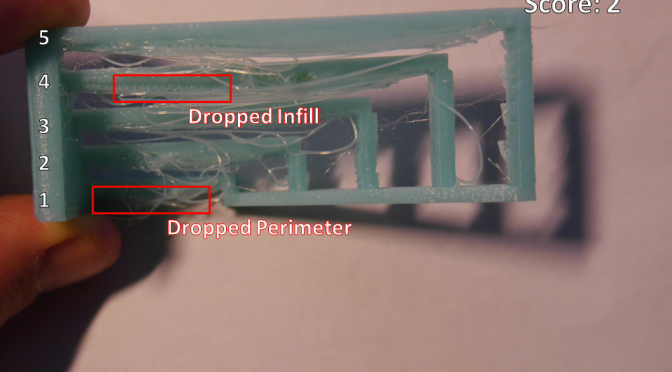

In the last couple of posts I described how I put a z-probe onto Squirty the RepRap. Adding the z-probe meant new wires. These wires ended up jumbled all over the place and occasionally got caught on the z-axis threaded rods, causing all manner of chaos to break out. The z-probe also requires a lot of clearance, which means that the printer carriage spends more time up at the top of the build area than it used to. Once up there, it has a nasty habit of bumping into the Melzi control board. To try and tidy things up, I collected all the wiring for the z-probe and ducted fan components together and designed a new set of Melzi holding clips.