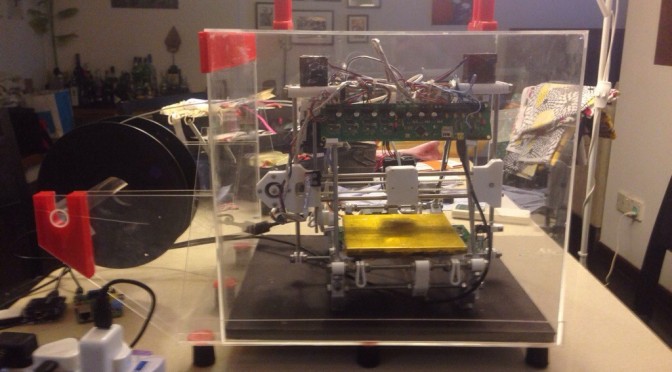

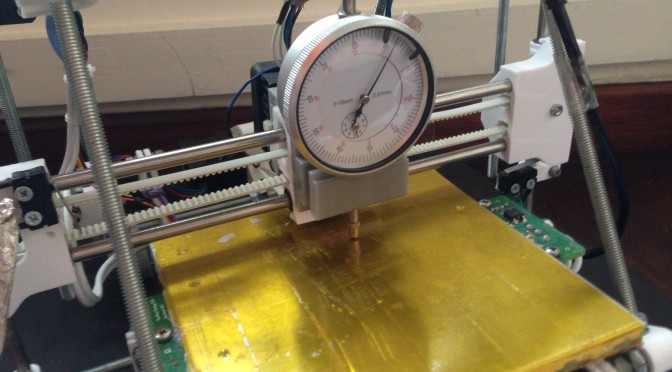

One of the most common questions that people ask you when you tell them that you have a 3D printer (shortly after they ask you can you print a gun) is how accurately can you print? My answer to this question has always been stolen from RepRapPro’s specifications page where it describes the accuracy of the RepRap Huxley as 0.1 mm. The various trials and tribulations that my friend Rob has experienced while assembling a 3D printer made from Squirty-printed parts has made me re-examine the answer to this question.

Rob suggested that I test the tolerance of the 3D printer by printing what he described as a Minecraft (TM) doughnut. This is a bit like a doughnut, only square. After printing one I could measure the inner and outer dimensions and compare it to the dimensions in the design to understand what the tolerance of the printer is. The idea of having an inner and outer dimension to measure is that you can tell if the plastic squidges slightly outside the boundary of the part – if this was the case the outside of the doughnut would be too big while the hole would be too small. This post describes my adventures with the aforementioned Minecraft doughnuts. Continue reading →